Gravity Die Casting

1. Features of Gravity Die Casting

Compared with Sand Casting and other methods the dimensional accuracy is excellent, products can be produced with less finishing allowance, a smoother casting surface, and fine grain size with less pin holes due to the faster cooling rate, which achieves excellent mechanical properties at lower costs.

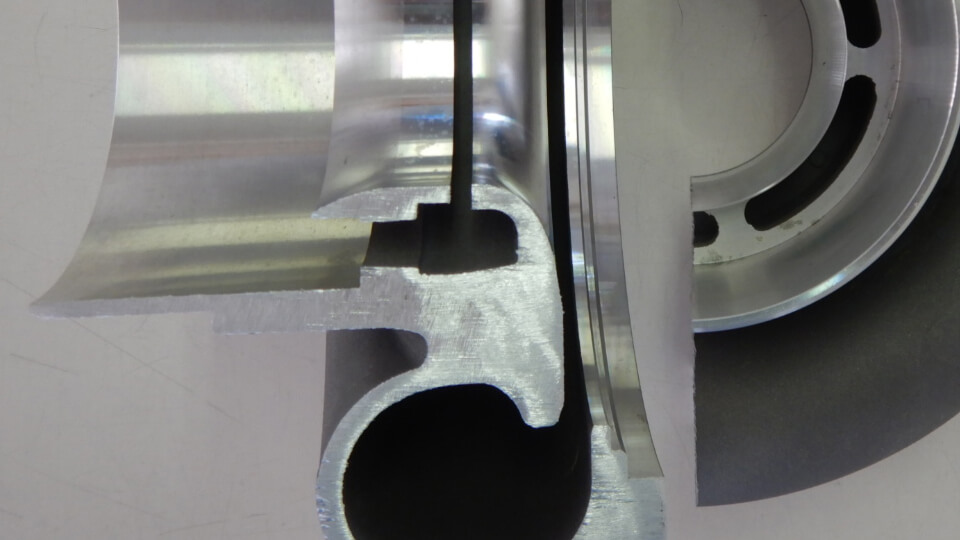

2. Thin Wall Thickness Compatibility

Mold costs are low. Hardness, which is difficult to achieve with die casting, can be guaranteed through a heat treatment process. In addition, the biggest feature of gravity casting is that it allows the use of shell cores, making it possible to mold complex internal shapes.

3.Response results

Achieves uniform quality from the vicinity of the casting surface to the center. Thick-wall compatibility, which overturns the conventional wisdom that the feature density becomes coarser toward the center of thick-walled parts. This increases the degree of freedom in product design and enables the creation of products with extremely small differences in strength between parts.

Casting Machine Specifications

Machine No. 1 (Tilting Type)

Internal dimensions: L700 x W400 x H900

- Cylinder diameter: Upper extrusion φ60, lower extrusion φ100

- Mainly casts products of 2.5 kg or less, and a continuous melting furnace is used as the molten bath.

- Equipped with an automatic air-cooling system.

Machine No. 2 (Tilting Type)

Internal dimensions: L700 x W800 x H800

- Cylinder diameter: Upper extrusion φ80

- Mainly casts multi-phase index products of 4.0 kg or less. A continuous melting furnace is used for the molten bath.

- Equipped with an automatic air-cooling system.

Machine No. 3 (Tilting Type)

Internal dimensions: L770 x W680 x H1,140

- Cylinder diameter: Upper extrusion φ100, lower extrusion φ140

- Mainly casts products of 4.0 kg or more. A 250 kg furnace is used for the molten bath.

- Equipped with an automatic air-cooling system.

Machine No. 4 (Tilting Type)

Internal dimensions: L900 x W430 x H880

- Cylinder diameter: Upper extrusion φ90, lower extrusion φ60

- Mainly casts products from 1.0 to 4.0 kg.A 250 kg furnace is used for the molten bath.

- Equipped with an automatic water-cooled system.

Machine No. 5 (Tilting Type)

Internal dimensions: L780 x W500 x H1,130

- Cylinder diameter: Upper extrusion φ100, lower extrusion φ100

- A FRAME dedicated machine.

- Equipped with an automatic water-cooled system.

Machine No. 6 (Tilting Type)

Internal dimensions: L950 x W680 x H1,250

- Cylinder diameter: Upper extrusion φ140, lower extrusion φ140

- Casts products of 3.0 kg or more.

- Equipped with an automatic water-cooled system and temperature controlled air-cooling system.